Pyrolysis/gasification of lignocellulosic biomass in fluidised beds/Entrained flow reactors

This research programm is a long collaboration with CEA-Energies nouvelles in Grenoble. The main objective is to develop experimental and modelling tools to support the design of pilot scale gasification units.Actions

PhD work of C. COUHERT

INP Toulouse, November the 30th 2007

Partner in the 3 years project GEM-GP2E H2 - Fuel cells, Ecole des Mines de Paris - P. Achard

Abstract: Pyrolysis is the first stage of any thermal treatment of biomass and governs the formation of synthesis gas for the production of electricity, hydrogen or liquid fuels. The objective of this work is to establish a link between the composition of a biomass and its pyrolysis gas. We study experimental flash pyrolysis and fix the conditions in which quantities of gas are maximal, while aiming at a regime without heat and mass transfer limitations (particles about 100 µm): temperature of 950°C and residence time of about 2 s. Then we try to predict gas yields of any biomass according to its composition, applicable in this situation where thermodynamic equilibrium is not reached. We show that an additivity law does not allow correlating gas yields of a biomass with fractions of cellulose, hemicellulose and lignin contained in this biomass. Several explanations are suggested and examined: difference of pyrolytic behaviour of the same compound according to the biomass from which it is extracted, interactions between compounds and influence of mineral matter. With the aim of industrial application, we study pyrolysis of millimetric and centimetric size particles, and make a numerical simulation of the reactions of pyrolysis gases reforming. This simulation shows that the choice of biomass affects the quantities of synthesis gas obtained.

Gasification in an entrained flow reactor of small wood particles, charcoal particles and torrefied wood particles

Partner in the 3 years Agence Nationale de la Recherche (ANR) project CINE-HT - CEA Grenoble

Post Doctoral work of C. Couhert

Fast pyrolysis of millimetric wood particles between 800 and 1000°C

PhD work of L. CHEN

December the 8th 2009

Abstract: The present work is part of a project of the French energy research centre Commissariat à l'Energie Atomique. The goal of the project is to develop processes of production of gaseous or liquid fuel from synthesis gas obtained by gasification of lignocellulosic biomass. The objective of the present work is to study the pyrolysis behaviour of millimetric biomass particles under the operating conditions encountered in fluidized bed or entrained flow gasifiers, namely high external heat flux (105 - 106 W?m-2) and high temperature (> 800°C). First, pyrolysis experiments are conducted at 800 and 950°C in a lab-scale drop tube reactor on wood particles between 350 and 800 µm. The results show that under the explored conditions, the increase of the particle size only increases the time required for pyrolysis but does not affect the product distribution during pyrolysis. Since in the pyrolysis experiments, the particle residence time cannot be directly measured, PTV (Particle Tracking Velocimetry) measurements are performed at room temperature to characterize the evolution of the particle size and density along pyrolysis and to validate a drag coefficient correlation for the particle residence time calculation. The optical measurements show that at the end of pyrolysis there is a decrease of particle density of 70 - 80% and of particle size of 25 - 40%. It is also proven that the particle slip velocity cannot be neglected and that the change of these particle properties must be taken into account for the calculation of the particle slip velocity and residence time. Finally, based on these experimental results, a 1D shrinking-core model is developed that is able to predict the solid/gas/tar yields and the residence time of a single particle along pyrolysis in the drop tube reactor. It is validated on both the pyrolysis and optical experiments. The model sensitivity analysis shows that even for millimetric particles, the accurate knowledge of the heat of pyrolysis, of the wood density and of the char thermal conductivity is essential.

High temperature gasification of millimetric wood particles between 800 and 1400°C

PhD work of S. SEPTIEN

November 2011

Abstract: Biomass gasification was studied in the conditions of an entrained flow reactor, namely at high heating rate and temperature. Experiments in a drop tube reactor were performed between 800°C and 1400°C, with wood particles of 0.35 mm and 0.80 mm size, under inert and steam containing - 25 mol% of H2O - atmospheres. These experiments were also simulated with a 1D model which gave good predictions. The collected solids, soot and char, were analyzed and characterized. This study highlights the importance of gas phase reactions on the yields of the final products, mainly gaseous compounds, in these conditions. These reactions are hydrocarbons cracking, reforming and polymerization, leading to soot formation, and water-gas shift. Char graphitization and deactivation were experimentally demonstrated. However, these phenomena have a negligible influence on char evolution in the drop tube reactor. Finally, the particle size was shown to have almost no influence on experimental results.

Synthesis of second generation biofuels: Study of the pyrolysis of centimeter-scale wood particles at high temperature

PhD work of G. GAUTHIER

November 2013

Abstract: Pyrolysis is a key step in the thermochemical conversion processes of biomass for the synthesis of second generation biofuels. The objective is to improve our understanding of the mechanisms of pyrolysis at the particle scale. It appears necessary to first get new data by controlling the operating conditions in order to secondly validate models. An experimental device has been developed to study the pyrolysis of wood centimeter-scale particle between 450 and 1050°C. The internal temperature, the mass and size of the particle, and instantaneous gas yields were monitored continuously. The products of pyrolysis were characterized. The model developed in a two dimensional system by the Catholic University of Louvain was chosen to describe the experimental conditions and simulate the results. Significant differences between model and experiments were observed. The comparison between simulated and experimental results and the results of a parametric study are used to identify ways to improve the reliability and the predictive ability of the simulations. The measurement of the particle thermal properties was one of the identified ways and was studied carefully. Correlations are proposed to describe the variations of both wood and char heat capacities and thermal conductivities with the pyrolysis temperature until 1050°C.

Effects of CO2 on the biomass pyro-gasification in High Heating Rate and Low Heating Rate Conditions

Partner in the Agence Nationale de la Recherche (ANR) 3 years project ReCO2

PhD work of C. GUIZANI

January 2016

Abstract: The present work deals about the effects of CO2 enriched atmospheres on biomass pyrolysis and char gasification reactions in High Heating Rate (HHR) and Low Heating Rate (LHR) conditions, at the biomass particle level. In the first part, we studied the effects of CO2 on the high temperature fast pyrolysis reaction and evaluate its effects on the pyrolysis rate, on the gas yield as well as on the char properties including chemical composition, texture and reactivity at 850°C. We focused also on the effects of CO2 on the HHR-char gasification reaction when injected as a co-reactant with steam. We studied the mixed atmosphere gasification reaction in CO2 and H2O for different atmosphere compositions. Finally, we imagined a hypothetical case of a pure CO2 operating gasifier. The case of a pure CO2 pyrogasification process was tackled experimentally and theoretically by numerical modelling with aim to provide pyrolysis and gasification characteristic reaction times, and to understand the unfolding of the global CO2 pyro-gasification reaction. In the second part, we were interested on the issue of LHR-char gasification in the presence of CO2 with two principal objectives: on one hand, providing reactivity data for practical gasification operations and on the other hand, understanding the gasification reaction mechanisms (in CO2, H2O and their mixtures) at the level of the char basic structural units (BSU). We examined the influence of particle size on the single atmosphere gasification in CO2 and H2O using the Thiele modulus approach. We also studied the effects of temperature and particle size on the char gasification in mixed atmosphere of CO2 and steam at 900°C. We also had a focus on the issue of cyclic atmosphere gasification and studied the effects of a prior CO2 gasification on the char reactivity towards H2O and vice versa. To further understand the char gasification mechanisms in single and mixed atmospheres of CO2 and H2O, we opted to monitor the evolution of the chemical, structural and textural char properties along the gasification in CO2, H2O and their mixtures. Deep char characterization were performed on small LHR-char particles partially gasified at 20%, 50% and 70% of conversion in CO2, H2O and their mixtures. These characterisations are of high interest as they shed light on the unfolding of the gasification reaction in CO2, H2O and their mixtures. Objectives : Drying, pyrolysis and gasification of wet wood-chips in fluidised bed conditions. Interactions between the three steps, and impact of complex atmospheres enriched with CO2

Pyrolysis and gasification of a solid recovered fuel (SRF) and its model materials

PhD work of O. SABOGAL SOSA

June 2022

Abstract: Solid waste materials that cannot be reused or recycled are increasingly used to produce Solid Recovered Fuels (SRF). They can be transformed by thermochemical processes such as gasification, thus producing a synthesis gas that can be used in cogeneration (heat and electricity) or for the synthesis of liquid or gaseous fuels. SRF constitute a raw material of interest that has been largely less studied than biomass in gasification. The objective of the thesis is to investigate the pyrolysis and gasification of SRF, in relation with their physical and chemical characteristics, under controlled operating conditions. For this purpose, a new laboratory-scale experimental device was developed. An experimental characterization and CFD calculations provided a complete description of the temperature profiles for the sample and the gas inside the reactor. Several model materials (wood, cardboard, polyethylene terephthalate, polyethylene, and polypropylene), often found in SRF, were studied separately, in an inert atmosphere and in the presence of air as an oxidizing agent. The yield and distribution of reaction products (char, gas species, and tar) were determined. Pyrolysis of wood/plastic mixtures showed an increased conversion of carbon to gaseous products in comparison with what would be expected with no interaction. Based on the experimental pyrolysis results for the individual model materials, a correlation was developed to predict the product yields as a function of the feedstock C, H and O contents.

The Entrained Flow Reactor (1000°C, left hand side) and the High Temperature (1600°C) Entrained Flow reactor (right hand side)

At Ecole des Mines d'Albi, France.

It enables the pyrolysis/combustion/gasification for several seconds of solid particles with size between 30 micro-m and several mm,

under inert or reactive atmospheres (including steam).

At the centre, a set of gas analysers including NDIR, FTIR, MicroGC, HCT by FID and psychrometer.

|

|

|

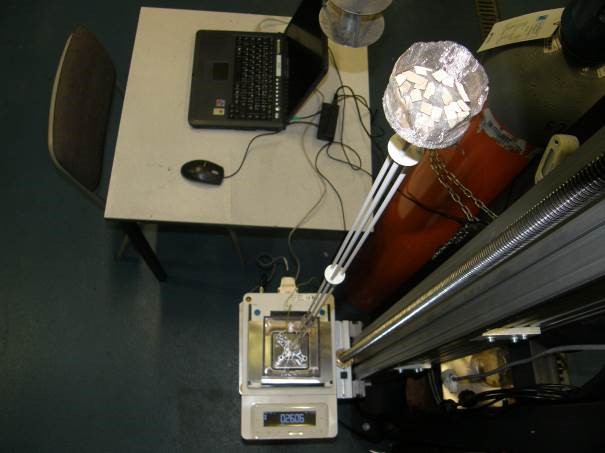

The "spoon furnace": the sample is placed in the quartz spoon (or on a grid support for a lighter system)

and introduced rapidly in the furnace at the left. The reaction atmosphere is controlled. At the exit of the reactor (not presented)

gases are stored in a sampling bag for further analysis using gas analysers including NDIR, FTIR, MicroGC, HCT by FID.

The mass of remaining solid is determined accurately.

Publications

Biomass pyrolysis experiments in an analytical entrained flow reactor between 1073 K and 1273 K

C. Dupont, J-M. Commandré, P. Gauthier, G. Boissonnet, S. Salvador, D. Schweich

Fuel, Volume 87, Issue 7, June 2008, Pages 1155-1164

Failure of the component additivity rule to predict gas yields of biomass in flash pyrolysis at 950°C.

Carole Couhert, Jean-Michel Commandré, Sylvain Salvador

Biomass and Bioenergy 33 (2009) 316-326

Is it possible to predict gas yields of any biomass after rapid pyrolysis at high temperature from its composition in cellulose, hemicellulose and lignin?

Carole Couhert, Jean-Michel Commandré, Sylvain Salvador

FUEL Vol.88, March 2009, pp. 408-417

Influence of Particle Size, Reactor Temperature and Gas Phase Reactions on Fast Pyrolysis of Beech Wood

Chen, Li; Dupont, Capucine; Salvador, Sylvain; Boissonnet, Guillaume; and Schweich, Daniel (2010)

International Journal of Chemical Reactor Engineering: Vol. 8, Article 10.

Pyrolysis of wood at high temperature: the influence of experimental parameters on gaseous products

J-M. Commandré, H. Lahmidi, S. Salvador , N. Dupassieux

Fuel Processing Technology, Volume 92, Issue 5, May 2011, Pages 837-844

Effect of particle size and temperature on wood biomass fast pyrolysis at high temperature (1000°C to 1400°C)

Santiago Septien, Sylvie Valin, Capucine Dupont, Marine Peyrot, Sylvain Salvador

FUEL, 2012 , vol. 97. - p.202-210 http://dx.doi.org/10.1016/j.fuel.2012.01.049

Experimental study on fast pyrolysis of free-falling millimetric biomass particles between 800 and 1000°C

Li Chen, Capucine Dupont, Sylvain Salvador, Guillaume Boissonnet, Daniel Schweich

FUEL, Vol. 106, p. 61-66, 2013.

The gasification reactivity of High-Heating-Rate Chars in single and mixed atmospheres of H2O and CO2

Guizani C., Escudero Sanz F.J., Salvador S.

FUEL, Vol. 108, p. 812-823, 2013.

Influence of steam on gasification of millimetric wood particles in a drop tube reactor: experiments and modelling

S. Septien, S. Valin, M. Peyrot, B. Spindler, S. Salvador

FUEL, Vol. 103, p.1080-1089, 2013.

Experimental and kinetic modeling analysis of pyrolysis of thick biomass particles

Guillaume Gauthier, Thierry Melkior, Sylvain Salvador, Michele Corbetta, Alessio Frassoldati, Sauro Pierucci and Eliseo Ranzi

Chemical Engineerng Transactions, Vol. 31. ISBN 978-88-95608-22-8; ISSN 1974-9791, 2013

Characterization of char and soot from millimetric wood particles pyrolysis in a drop tube reactor between 800°C and 1400°C

Santiago Septien, Sylvie Valin, Marine Peyrot, Capucine Dupont, Sylvain Salvador

Fuel 121, pp. 216-224, 2014.

Pyrolysis of centimetre-scale wood particles: new experimental developments and results

GAUTHIER Guillaume, MELKIOR Thierry, GRATEAU Maguelone, THIERY Sébastien, SALVADOR Sylvain

Journal of Analytical and Applied Pyrolysis, Vol. 104, p. 521-530, 2013.

Gasification of wood char in single and mixed atmospheres of H20 and CO2

TAGUTCHOU Jean-Philippe, VAN DE STEENE Laurent, ESCUDERO SANZ Javier, SALVADOR Sylvain

Energy Sources, PART A, Vol. 35, N° 13, p. 1266-1276, 2013

Effects of CO2 on biomass fast pyrolysis : reaction rate, gas yields and char reactive properties

Chamseddine Guizani, Francisco Javier Escudero Sanz, Sylvain Salvador

Fuel 116, pp.310-320, 2014.

Gasification of woody biomass under high heating rate conditions in pure CO2: Experiments and modelling

Chamseddine Guizani, Olivier Louisnard, Francisco Javier Escudero Sanz, Sylvain Salvador

Biomass and Bioenergy 83, pp.169-182, 2015.

Biomass Gasification in Entrained Flow Reactor: Influence of Wood Particle Size

Joseph Billaud, Sylvie Valin, Gilles Ratel, Marine Peyrot, Fredrik Weiland et al.

Chemical Engineering Transactions, AIDIC, Chemical Engineering Transactions 50, pp.37-42, 2016.

Influence of H2O, CO2 and O-2 addition on biomass gasification in entrained flow reactor conditions: Experiments and modelling

Joseph Billaud, Sylvie Valin, Marine Peyrot, Sylvain Salvador

Fuel 166, pp.166-178, 2016.

The Heat Treatment Severity Index: A new metric correlated to the properties of biochars obtained from entrained flow pyrolysis of biomass

Chamseddine Guizani, Mejdi Jeguirim, Sylvie Valin, Marine Peyrot, Sylvain Salvador

Fuel 244, pp.61-68, 2019.

Design and thermal characterization of an induction-heated reactor for pyro-gasification of solid waste

SOSA SABOGAL Oscar, VALIN Sylvie, THIERY Sébastien, SALVADOR Sylvain

Chemical engineering design and research, 173 (2021) 206-214

Pyrolysis of solid waste and its components in a lab scale induction-heating reactor.

Oscar Sosa Sabogal, Sylvie Valin, Sébastien Thiery, Sylvain Salvador.

Detritus, Cisa Publisher, 2021, pp.107-112. (10.31025/2611-4135/2021.15094) (hal-03328491)

Co-pyrolysis of biomass and plastics from waste in an induction heated reactor

Oscar Sosa Sabogal, S Valin, S Thiery, Sylvain Salvador.

THESSALONIKI 2021 - 8th International Conference on Sustainable Solid Waste Management, Jun 2021, Thessaloniki, Greece

Congress

Heat and Mass Balance Process Model of the LIFT-OFF Biomass Gasification CHP Plant

Martin W. Fock, Lasse Tobiasen, S. Lecomte, S. Salvador, L. Van de steene

2nd World Conference and Tecnology Exhibition on Biomass for Energy, Industry and Climate Protection, Rome, Italy, 10-14 May 2004.

Flash pyrolysis of the three components of biomass - cellulose, lignin and xylan - in an entrained flow reactor:

singly and in two-component mixtures.

C. Couhert, S. Salvador

17th International Symposium on Analytical & Applied Pyrolysis. May 21 to 26, 2006 - Budapest, Hungary. Oral presentation.

High temperature pyrolysis of woody biomass in an entrained flow reactor

H. Lahmidi, J-M. Commandré, N. Dupassieux, S. Salvador

17th International Symposium on Analytical & Applied Pyrolysis. May 21 to 26, 2006 - Budapest, Hungary. Poster

Peut-on prédire le comportement d'une biomasse lignocellulosique lors de la pyrolyse flash à haute température ?

Couhert C., Commandré J-M. et Salvador S.

Récents Progrès en Génie des Procédés - Numéro 96 - 2007, ISBN 2-910239-70-5, Ed. SFGP, Paris, France

The influence of particle diameter on gas yields and on the reactivity of chars obtained by rapid pyrolysis of wood

J-M. Commandré, C. Couhert, S. Salvador

15th European Biomass Conference & Exhibition, Berlin, 7-11 May 2007. Poster

Rapid pyrolysis of biomass for the production of fuel gas: effect of the nature of biomass, of particle size and

of the gaseous atmosphere.

Carole COUHERT, Jean-Michel COMMANDRE, Sylvain SALVADOR

18th International Symposium on Analytical and Applied Pyrolysis, Canary Islands, Spain. 18-23 may 2008.

Experimental Study of Biomass Fast Pyrolysis: Influence of Temperature and Particle Size

Li CHEN, Capucine DUPONT, Guillaume BOISSONNET, Sylvain SALVADOR, Daniel SCHWEICH

18th International Symposium on Analytical and Applied Pyrolysis, Canary Islands, Spain. 18-23 may 2008. Poster

Fast pyrolysis at gasification conditions: influence of particle size, reactor temperature and gas phase reactions

Li Chen, Capucine Dupont, Sylvain Salvador, Guillaume Boissonnet and Daniel Schweich

Bioenergy - II: Fuels and Chemicals From Renewable Resources

March 8-13, 2009 Rio de Janeiro, Brazil

Oral presentation

FAST PYROLYSIS OF CENTIMETRIC WOOD PARTICLES

G. GAUTHIER, T. MELKIOR, B. SPINDLER, M. GRATEAU, S. SALVADOR

Multiscale Approaches for Process Innovation - MAPI, 25 - 27 January 2012, IFP Energies nouvelles-Lyon, France

PYROLYSIS OF CENTIMETRIC WOOD PARTICLES

Guillaume GAUTHIER, Thierry MELKIOR, Bertrand SPINDLER, Maguelone GRATEAU and Sylvain SALVADOR.

EUBC&E2012, 20th European Biomass Conference and Exhibition, Milano, 18-22 June 2012, oral presentation

PYROLYSIS OF CENTIMETRIC WOOD PARTICLES

G. GAUTHIER, T. MELKIOR, M. GRATEAU, B. SPINDLER and S. SALVADOR

19th International Symposium on Analytical and Applied Pyrolysis, Linz, Austria, 21-25 May 2012. Oral presentation.

CHARACTERISATION OF SOOT AND CHAR FROM WOOD FAST PYROLYSIS BETWEEN 1000°C AND 1400°C

Santiago SEPTIEN, Sylvie VALIN, Marine PEYROT, Sylvain SALVADOR

19th International Symposium on Analytical and Applied Pyrolysis, Linz, Austria, 21-25 May 2012. Oral presentation.

Pyrolyse à haute température de particules de bois centimétriques

Guillaume GAUTHIER, Thierry MELKIOR, Maguelone GRATEAU, Sébastien THIERY, Sylvain SALVADOR

SFGP 2013 -14ème Congrès français en génie des procédés, Oct 2013, Lyon, France. Art.2013120061-9 p

Experimental and Modeling Study of the Gasification of Char from Millimetric Wood Chips Pyrolysis

S. Septien, F. J. Escudero Sanz, S. Salvador

BioEnergy IV: Innovations in Biomass Conversion for Heat, Power, Fuels and Chemicals, June 9-14, 2013,

Basiliani Resort, Otranto, Italy

Confrontation of experimental and modeling studies on pyrolysis of centimetric wood particles

Guillaume GAUTHIER, Julien BLONDEAU, Thierry MELKIOR, Hervé JEANMART, and Sylvain SALVADOR.

21st European Biomass Conference and Exhibition, Copenhagen, 3-7 June 2013. Oral presentation.

Comparison of experimental and modeling studies on pyrolysis of centimeter-scale wood particles

Guillaume GAUTHIER, Thierry MELKIOR and Sylvain SALVADOR.

TCBIOMASS 2013, the International Conference on Thermochemical Biomass Conversion Science, 3-6 septembre 2013,

Chicago, USA.

Pyro-gasification of thin wood-chips in pure CO2: experiments and modelling

Chamseddine Guizani, Olivier Louisnard, Francisco Javier Escudero Sanz, Sylvain Salvador, D. Hermany

IREC'2014 - 5th International Renewable Energy Congress, May 2014, Hammamet, Tunisia. 6 p

Biomass Gasification Between 800 and 1400 degrees C in the Presence of O-2: Drop Tube Reactor Experiments and Simulation

Joseph Billaud, Sylvie Valin, Gilles Ratel, Sebastien Thiery, Sylvain Salvador

ICONBM - International Conference on Biomass, Pts 1 and 2, Florence, Italy. p.163-168, May 2014.

Biomass gasification between 800 and 1400 °C in the presence of O2: drop tube reactor experiments and simulation

Joseph BILLAUD, Sylvie VALIN, Gilles RATEL, Sébastien THIERY, Sylvain SALVADOR

Pisa, 2014, French-Italian meeting of IFRF, poster

Experimental developments and modelling of the pyrolysis of centimetric wood particles

Thierry MELKIOR, Guillaume GAUTHIER, Sylvain SALVADOR

icomBM: International Conference on Biomass, 4-7 May 2014, Florence, Italy

Chemical Engineering Transactions, vol. 37, 2014

BIOMASS GASIFICATION IN PRESENCE OF CO2, H2O OR O2 AT HIGH TEMPERATURE IN ENTRAINED FLOW REACTOR: EXPERIMENT AND MODELLING

Billaud Joseph, Valin Sylvie, Peyrot Marine, Salvador Sylvain

The 18th IFRF Members' Conference, 1st-3rd June 2015, Freising, Germany. Oral presentation and proceedings.

Biomass gasification in entrained flow reactor: influence of wood particle size

J. Billaud, S. Valin, G. Ratel, M. Peyrot, F. Weiland, H. Hedman, S. Salvador

IConBM2016, 2nd International Conference on BIOMASS, 19-22 June 2016, Giardini Naxos-Taormina, Sicily, Italy

WOODY BIOMASS FAST PYROLYSIS IN A DROP TUBE REACTOR

C. Guizani, S. Valin, M. Peyrot, G. Ratel, S. Salvador

21st International Symposium on Analytical and Applied Pyrolysis, Nancy France, 2016

The GENEPI PROJECT: an innovative PLATFORM of feedstock pretreatment by grinding and torrefaction,

coupled with an entrained-flow reactor (EFR) for gasification

Thierry CHATAING, Thierry MELKIOR, Gilles RATEL, Jean-Michel COMMANDRE, Sylvain Salvador

EUBCE 2017. 25th European Biomass. Conference & Exhibition. 12-15 June. Stockholm